Contact Persons

Address:

Kettenfabrik Unna GmbH & Co. KG

Max-Planck-Str. 2

59423 Unna

Phone:+49 (0) 2303-8806-0

Fax:+49 (0) 2303-8806-88

E-Mail: information@ketten.com

The running of the chain around the wheels causes wear of the articulations by the angle – slide movements of the bolts. Due to that fact lubrication of articulated chains is important to guarantee long life time and satisfactory service. The lubricant satisfies several functions: It separates pins and bushes surfaces, allowing easy rotation, then it damps and decreases sudden shocks between pins and bushes and chain and wheels and it might cool and clean the chain.

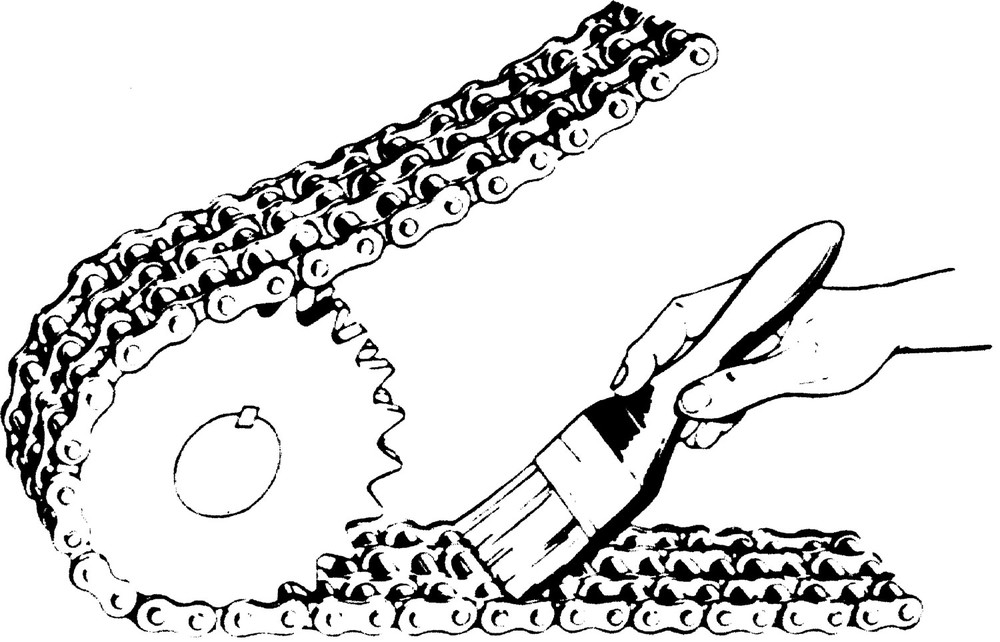

To obtain a good lubrication, oil must penetrate into articulations (B); it is not enough to lubricate the rollers (A). Oil must be applied to the inside surfaces of the chain at the edges of the link plates.

A pure mineral oil is recommended. Heavy oils and grease are not recommended, but may be foreseen for special applications (especially if the surrounding conditions contain dust, like lime, flour, talcum etc). We recommend the following lubricant viscosities for different temperatures:

| Temperature in °C | Viscosity |

| - 5 up to 25 | SAE 30 |

| 25 up to 45 | SAE 40 |

| 45 up to 65 | SAE 50 |

| low joint surface pressure, high chain speed | low viscosity |

| high joint surface pressure, low chain speed | high viscosity |

| low temperature | low viscosity |

| high temperature | high viscosity |

Manual lubrication: For speed up to 0.5 m/sec. Oil is applied with an oil can or brush, periodically (advise once every 8 working hours).

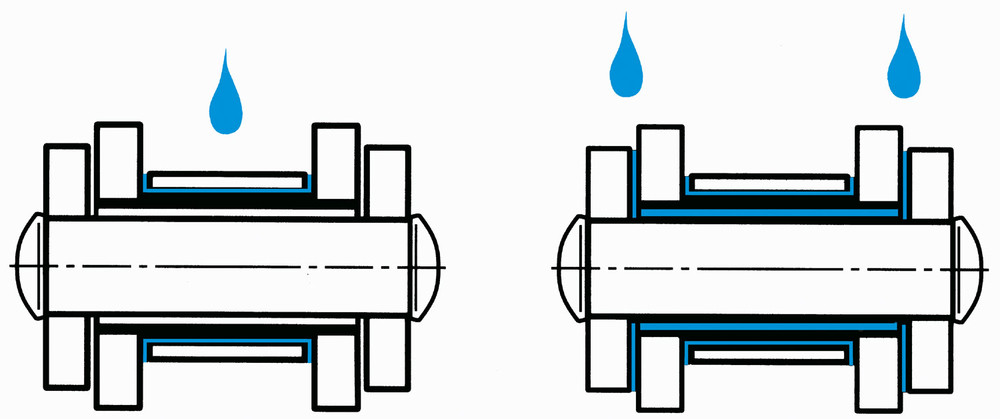

Drip lubrication: For speed up to 1.5 m/sec. Oil drip delivery should be regulated to assure uniform lubrication between 4 and 10 drops per minute.

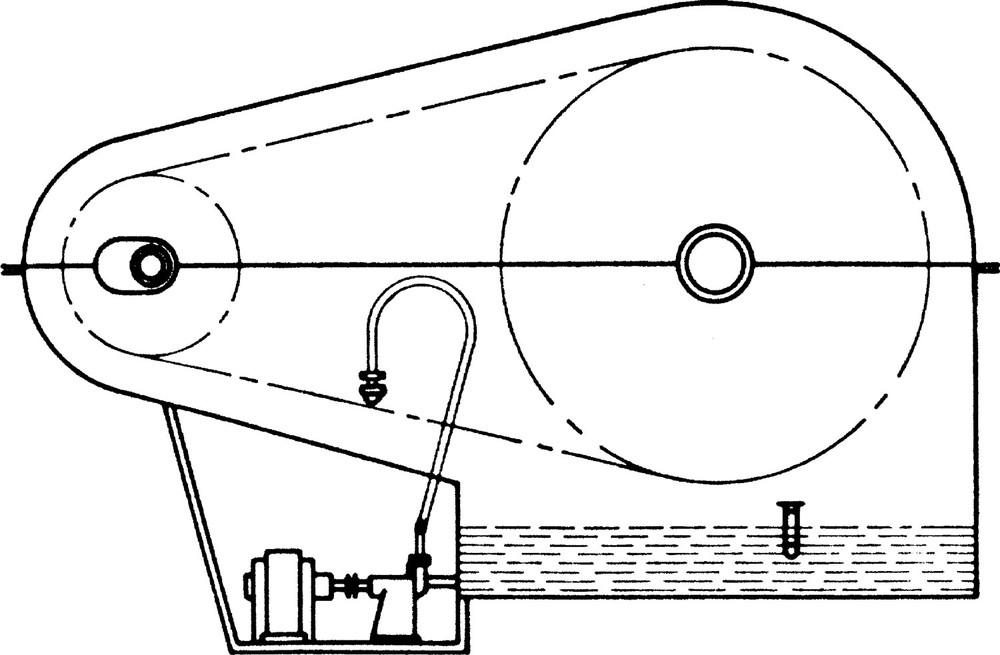

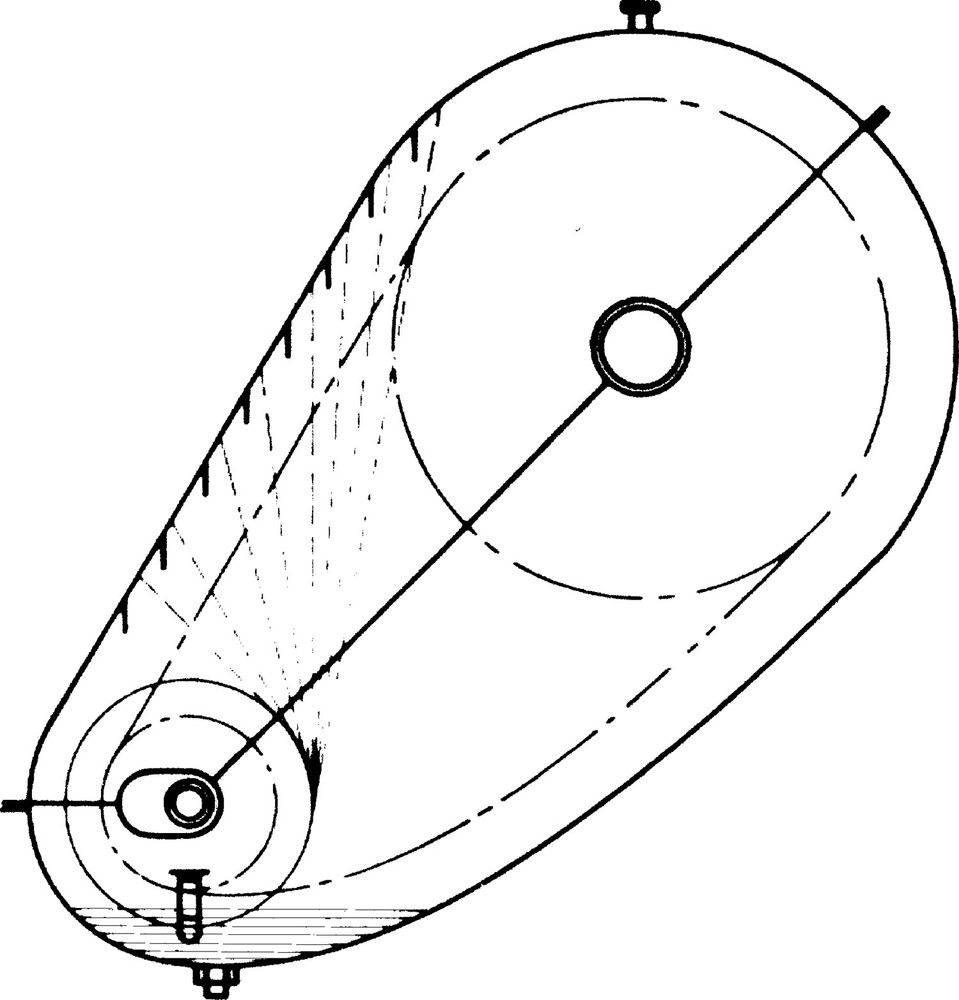

Oil bath or disc lubrication: For speed up to 8 m/sec. In oil bath the lower strand of chain runs through a bath of oil whose level is kept at about the chain pitch line (deeper dipping is not allowed due to warming and oxidation of the oil). Disc type lubrication uses a rotating disc dipping in an oil bath. The disc picks up oil from a sump and deposits it into the chain. The disc diameter shall be selected to keep a rotatif speed of 3 m/sec. minimum to 40 m/sec. maximum.

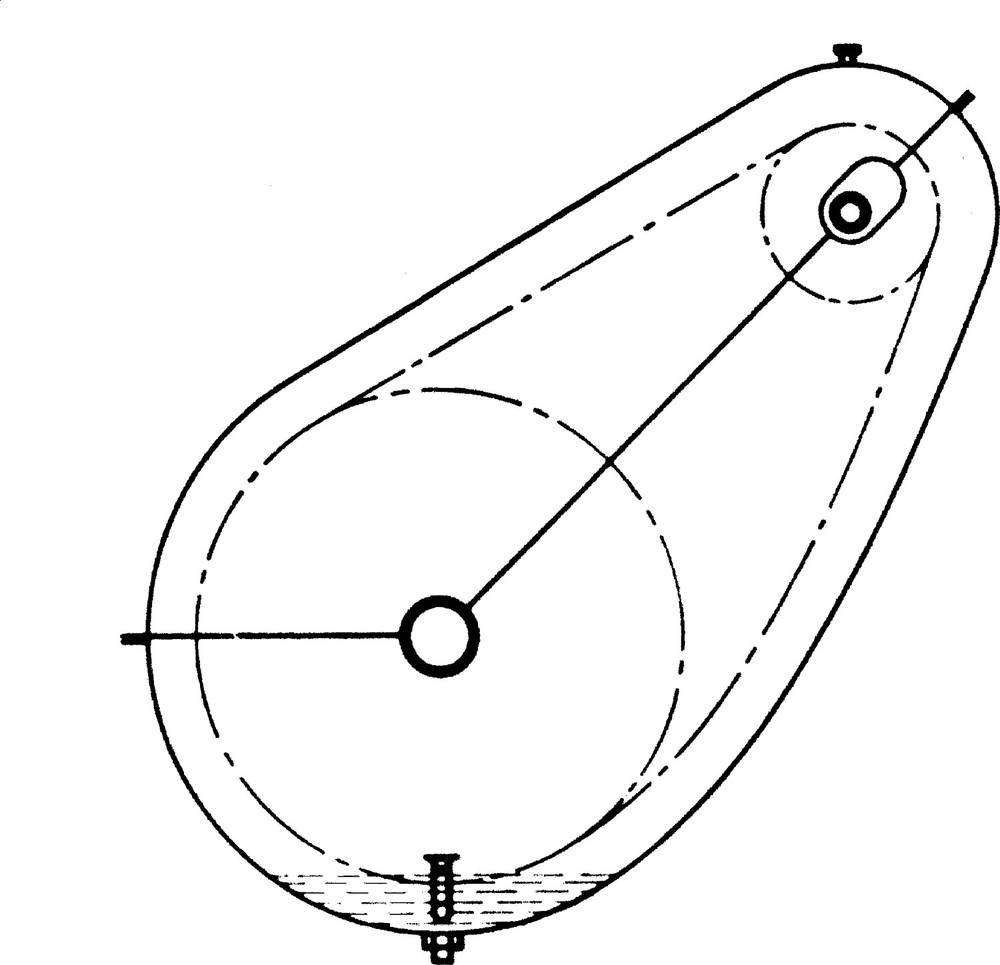

Forced lubrication: For speed more than 8 m/sec. Forced oil feed lubrication is the most effective system. Oil is supplied under pressure by a pump and continuously sprayed onto the chain. The oil should be applied inside the chain loop and at the lower strand just short of the point of engaging the sprocket.