Contact Persons

Address:

Kettenfabrik Unna GmbH & Co. KG

Max-Planck-Str. 2

59423 Unna

Phone:+49 (0) 2303-8806-0

Fax:+49 (0) 2303-8806-88

E-Mail: information@ketten.com

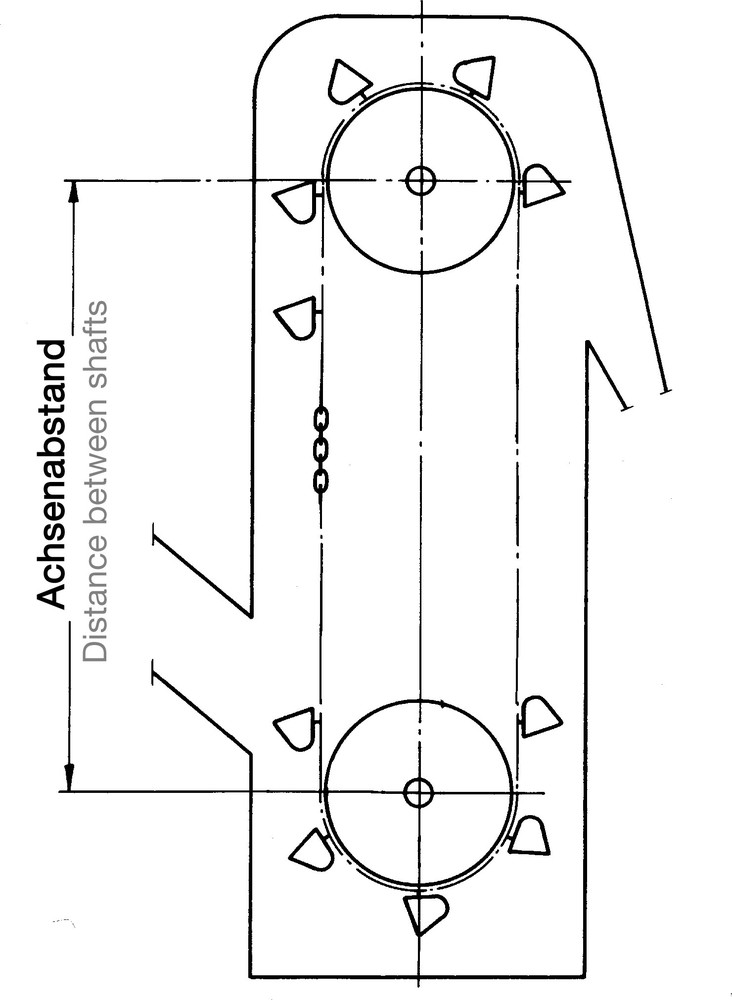

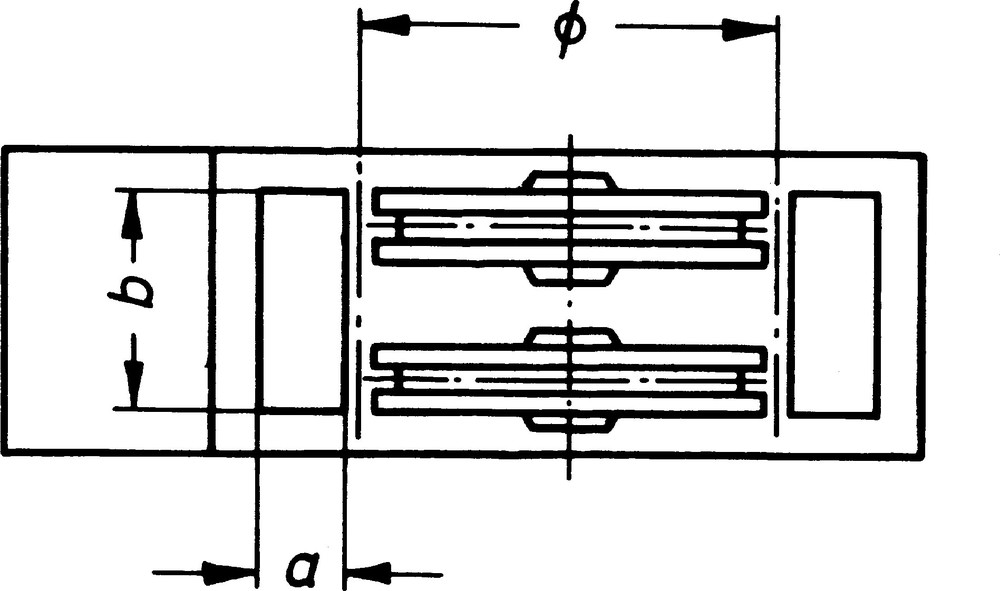

| Bucket b/mm x a/mm | Tolerance mm | Associated Chain with Measurements as per DIN 764 Nominal Diameter x Pitch mm | No. of Lnks n¹ | Associated Chain Shackle as per DIN 5699/745 Toothed mm | Associated Chain Shackle as per DIN 5699/745 Non Toothed mm |

|

160 x 160

|

500

|

10 x 35

|

9

|

35

|

45

|

|

200 x 160

|

500

|

13 x 45

|

9

|

45

|

56

|

|

250 x 200

|

630

|

16 x 56

|

9

|

56

|

63

|

|

315 x 200

|

630

|

18 x 63

|

9

|

63

|

70

|

|

400 x 224

|

710

|

20 x 70

|

7

|

70

|

80

|

|

500 x 250

|

800

|

23 x 80

|

7

|

80

|

91

|

|

630 x 280

|

900

|

26 x 91

|

7

|

91

|

105

|

|

800 x 315

|

1000

|

30 x 105

|

7

|

105

|

126

|

|

1000 x 355

|

1250

|

36 x 126

|

7

|

126

|

136

|

|

1400 x 425

|

1400/1500

|

42 x 147

|

7

|

147

|

147

|

|

1600 x 450

|

1500

|

42 x 147

|

7

|

147

|

147

|

| KU-Qualities | Chain ends KU 4 | Chain ends KU 5 | Chain brackets KU 4 | Chain brackets KU 5 |

| Proof strength N/mm² |

125

|

150

|

125

|

2404)

|

| Breaking strength N/mm² |

250

|

3703)

|

280

|

4004)

|

| Surface hardness in the back of the bracket |

240-360

|

300-360

|

||

| Surface hardness HV 30 in the rounding |

8001)

|

8001)

|

> 600

|

> 600

|

| Carburizing depth HTÄ |

0,1

|

0,1

|

||

| Hardening depth EHT |

0,062)

|

0,062)

|

0,1

|

0,1

|

| Material |

manganese steel

|

Chrome-Nickel alloyed super-refined steel

|

fine grained heat treatable steel

|

Chrome-Molybdane alloyed super-refined steel

|