Contact Persons

Address:

Kettenfabrik Unna GmbH & Co. KG

Max-Planck-Str. 2

59423 Unna

Phone:+49 (0) 2303-8806-0

Fax:+49 (0) 2303-8806-88

E-Mail: information@ketten.com

Chains tested perrsuant to German standards DIN 763 or DIN 766 are suitable for the lifting of loads. However, chains tested pursuant to DIN 763 are only suitable for static suspensions, meaning that they are not to be used as load suspensions or lifting equipment within the meaning of DIN 15003 in connection with cranes or hoists, this therefore meaning that they are not to be used for any dynamical lifting processes whatsoever.

Chains tested pursuant to DIN 766 are approved for all lifting processes, including dynamical processes.

Chains pursuant to DIN 5685 without load tests are not to be used as load suspension, meaning that they are not to be used as load suspensions or lifting equipment within the meaning of DIN 15003 in connection with cranes or hoists, this therefore meaning that they are not to be used for any lifting processes whatsoever. The chains have not been tested for strength within the meaning of DIN 685-3. However, all 3 parts of DIN 5685 stipulates a computed, static load capacity in the corresponding annexes. The user has sole responsibility should these chains be subjected to static loads, e.g. as a suspension for lighting fixtures, hanging baskets, etc.

Kettenfabrik Unna delivers stainless steel chains usually in the following execution:

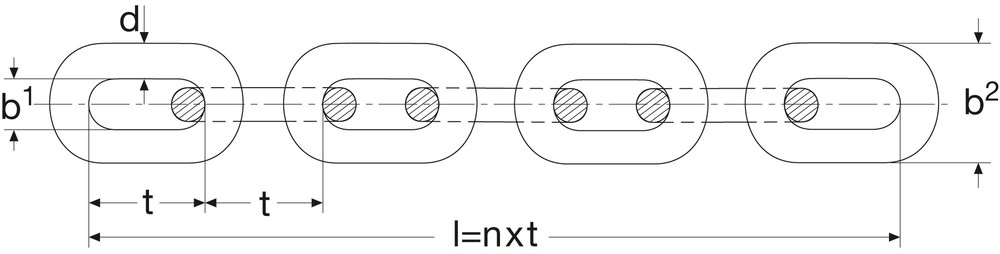

| d mm | Tolerance mm | t mm | Tolerance mm | b1 min. mm | b2 max. mm | Weight kg/100m | WLL kg | Proofload kN | Breaking load kN |

|

4

|

± 0,2

|

16

|

+0,3/-0,2

|

4,8

|

13,6

|

32

|

200

|

5

|

8

|

|

5

|

± 0,2

|

18,5

|

+,04/-0,2

|

6,0

|

17,0

|

50

|

320

|

8

|

12,5

|

|

6

|

± 0,2

|

18,5

|

+,04/-0,2

|

7,2

|

20,4

|

80

|

400

|

10

|

16

|

|

7

|

± 0,3

|

22

|

+,04/-0,2

|

8,4

|

23,8

|

110

|

630

|

16

|

25

|

|

8

|

± 0,3

|

24

|

+,04/-0,2

|

9,6

|

27,2

|

140

|

800

|

20

|

32

|

|

10

|

± 0,4

|

28

|

+0,5/-0,3

|

12,0

|

36,0

|

230

|

1.250

|

32

|

50

|

|

13

|

± 0,5

|

36

|

+0,6/-0,3

|

15,6

|

47,0

|

390

|

2.000

|

50

|

80

|

|

16

|

± 0,6

|

45

|

+0,8/-0,4

|

19,2

|

58,0

|

580

|

3.200

|

80

|

125

|

|

18

|

± 0,9

|

50

|

+0,8/-0,4

|

21,6

|

65,0

|

740

|

4.000

|

100

|

160

|

|

20

|

± 1,0

|

56

|

+1,0/-0,5

|

24,0

|

72,0

|

900

|

5.000

|

125

|

200

|

|

23

|

± 1,2

|

64

|

+1,1/-0,5

|

27,6

|

83,0

|

1.200

|

6.300

|

160

|

250

|